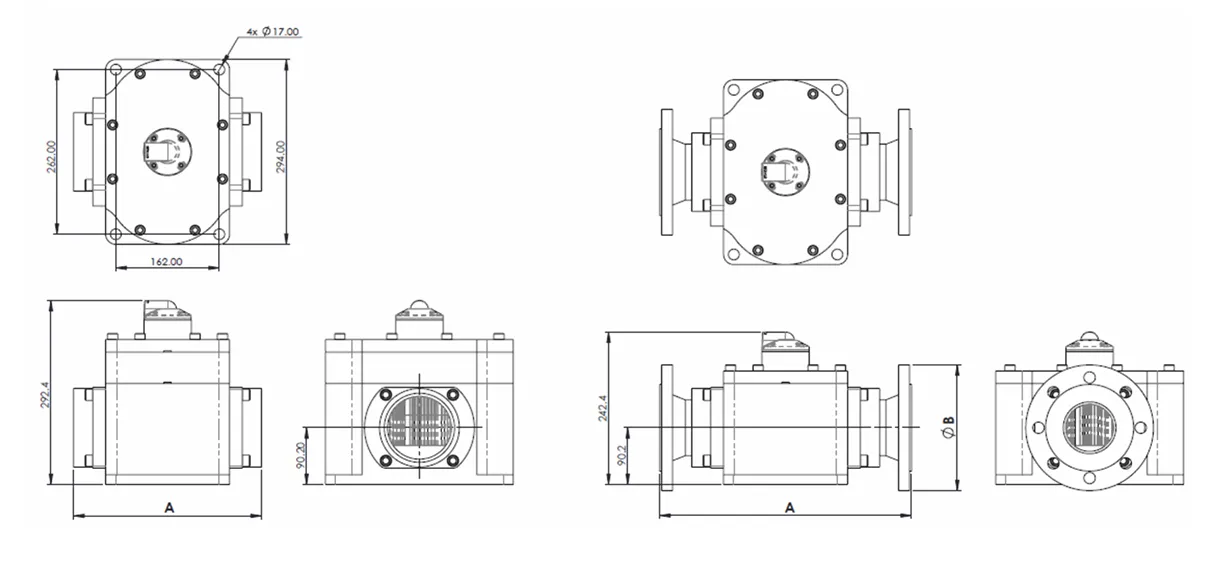

| Nominal size ( inches) | TG080 (3") | TG100 (4") | |||

|---|---|---|---|---|---|

| Flow range (LPIM) Iitres/min) | 25-700 | 50-1500 | |||

| Flow range (GPM) US gal/min) | 6.5 200 | 13 - 400 | |||

| Accuracy @ 3cp | ± 0.5% of reading (t0.25o Of reading over 6:1 turndown) | ||||

| Repeatability | Typically, t 0.03% of reading | ||||

| Temperature range | -30°C +120°C(-22F- +250°F) | ||||

| Maximum pressure | Bar (psi) | ||||

| Aluminium meters | 15 (220) | 15 (220) | |||

| Stainless Steel | 20 (290) | 20 (290) | |||

| Electrical - for pulse meters (see below for optional outputs) | |||||

| Output pulse resolution | pulses/ litre (pulses / US gallon) nominal | ||||

| Reed switch | 2.8 (10.6) | 1.4 (5.3) | |||

| Hall effect | 11.2 (42.5) | 5.6(21.5) | |||

| Quadrature Hall Effect option | 5.6 (21.2) | 2.3 (10.6) | |||

| Reed sWitch output | 30Vdc x 200mA max. (maximum thermal shock 10C (18*F)/minute) | ||||

| Hall effect output (NPN) | 3 wire open collector, 5~24Vdc max., 20mA max. | ||||

| Optional outputs | 4~20mA, Scaled pulse, quadrature pulse, flow alarms or two stage batch control | ||||

| Physical | |||||

| Protection class | IP66/67 (NEMA4XI, optional Ex I| 2GExEx d IIC T6 to T4, Ex II 1G Ex ia IC T2 or T4 Ga. Integral readouts can be supplied to either classification. | ||||

| Overall dimensions | Refer Below | ||||

| Recommended filtration | 350 microns (40 mesh) | ||||